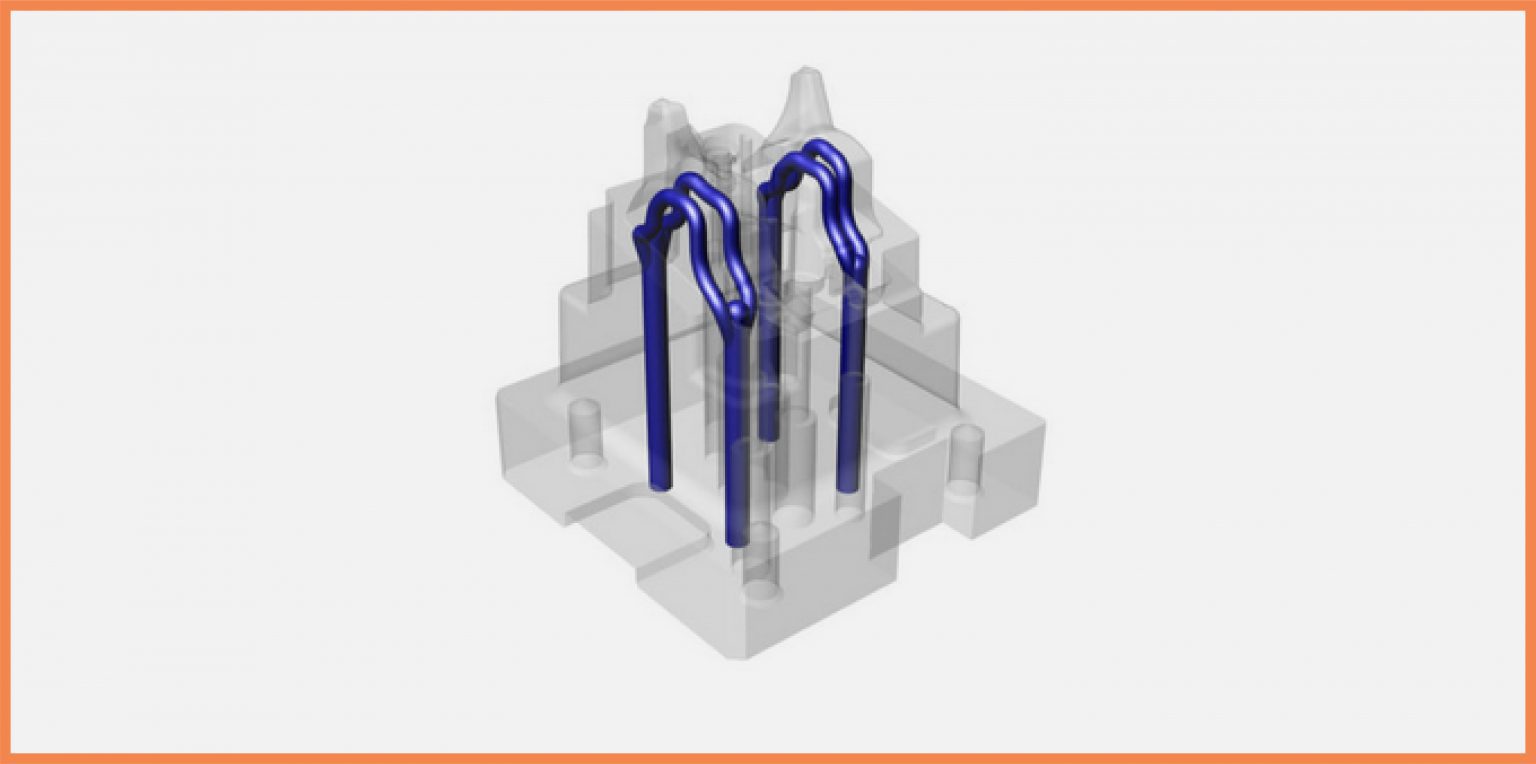

Conformally Cooled Inserts

H-13 Components can design and manufacture your conformally cooled inserts for heat defect remediation and cycle time reduction. Conformally cooled inserts are manufactured via a number of different methods. We offer both additive manufacturing and hermetic sealing depending on the part geometry, function and cost profile.

When to Use Conformal Cooling

- Most cycle times in HPDC can be reduced using conventional methods,

- however; conformal cooling can be highly effective in cooling the shot biscuit faster

- Slide cores are a frequently utilized location of conformal cooling

- Die soldering occurs when tool steel reaches 1100-F

- Hot areas are most easily identified with simulations