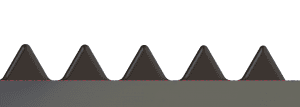

Chill Vent Serration Geometrics

Flat Profile for Resistance

Increased Height for Farther Travel

Greater Radius for Metal Flow

The critical functional portion of a chill vent or vacuum block is the washboard pattern formed by serrations. The serrations on the male side of the chill vent or vacuum block insert into the female side to form a gap for air flow while providing resistance to the molten metal. The serrations can be of any size or geometry, with varying advantages according to the need. The gap is the cross sectional area created by the meeting of the male and female serrations when die is closed. The gap is the functional area for air evacuation and metal flow. A gap that is too large may allow the molten metal to spit. A gap that is too small will constrict air evacuation. The smallest cross section or gap in a serration pattern sets the limit of flow capacity for air evacuation. There is no magic number for a gap which makes it more effective than another gap. The overall evacuation area provided by a chill vent or vacuum block is defined by the gap multiplied by the width of the serrations.